Expanded polystyrene, mainly called EPS, is used in various applications in our daily lives. EPS is light and convenient, and more importantly, it can be reused after cleaning. EPS is 100% recyclable.

With the maturity of technology, the recovery rate of EPS has increased in recent years. Many industries have begun to pay more attention to the recycling of foam. With the increasing application of foam recycling machines. EPS has become popular again. Let us take a look at its wide range of applications!

Table of Contents

package

EPS is the most common material in the packaging industry. Its excellent shock absorption characteristics make it very suitable for storing and transporting fragile and expensive items, such as electronic equipment, wine, etc. Its excellent thermal and moisture-proof properties can extend the freshness of perishable products, such as agricultural products and seafood.

In addition, its pressure resistance means that EPS is ideal for stackable packaging goods. Most of the EPS packaging made in Australia is used for the transportation of fruits, vegetables, and seafood. EPS packaging is widely used in domestic and export markets.

At present, the main recycling method is re-granulating waste EPS foam packaging into EPS pellets through crushing, melting, and then adding corresponding non-additive to process them into other products. For the above-mentioned recycling method, a professional recycling machine EPS foam densifier is required.

Building Construction

EPS is inherently inert, so it does not cause any chemical reactions. Since it does not attract any pests, it can be easily used in the construction industry. It is also closed cell, so when used as a core material, it will absorb very little water and in return will not promote mold or rot.

Other applications

foam recycling machine

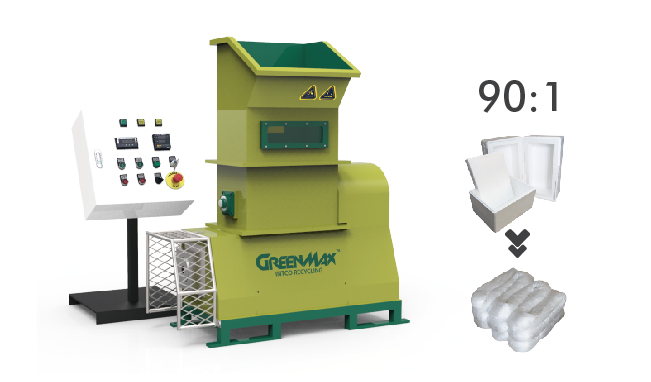

A foam densifier is a foam melting machine specialized in crushing and melting waste foam. It can handle various foam materials. The machine foam densifier can melt waste foam into dense ingots at a ratio of 90:1.

Its operation process is simple and safe. The double-shaft crushing knife in the foam melting machine can effectively crush the polystyrene material into smaller pieces and enter the screw, and then enter the main machine and rotate at high speed through the screw.

The material is heated by the mica heater, and then the molten material is continuously conveyed. When the square box is formed, the material begins to cool, the square is retracted from the box to form the foam, and the cutting process is automatically cut according to the required length to complete the production process.

This utility foam densifier has the advantages of high efficiency, space-saving, convenient transportation, and environmentally friendly operation.