GREENMAX Styrofoam densifier is becoming more and more popular in the field of foam recycling. In addition to its reliable and professional quality, it is also due to its continuous improvement. Following is the improvement of the crushing knife on the Styrofoam densifier.

Before volume reduction, the foams with different shapes, densities and properties must be crushed. Among them, PE foam used as packaging and shock-absorbing materials has good toughness, which increases the difficulty of crushing in the recycling process, as it can withstand certain deformation, and the conventional crushing mechanism can tear large pieces of materials when processing PE foam materials.

However, it can not be further crushed into a smaller size of 3 to 5cm, and the crushed materials are also easily wrapped around the crushing blade, which will adversely affect the subsequent production.

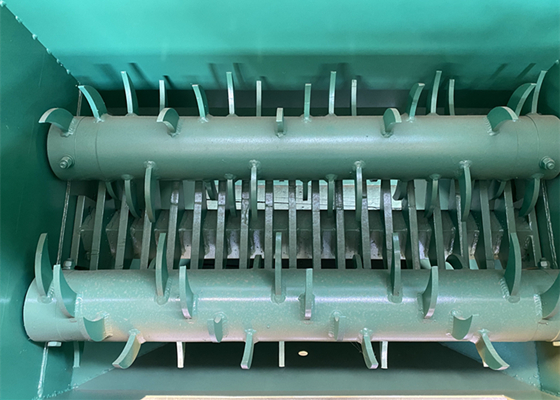

GREENMAX Styrofoam densifier has designed a special crushing structure for this situation. It consists of a pair of counter-rotating crushing knives and a fixed stationary knife below it. The crushing knives are set with angled staggered single head blade. The tip of the blade is made up of two arcs, and the shape of the blade is thinner and shorter than the conventional crushing blade.

The gap between the moving knife and the fixed knife can ensure that the crushed material reaches the required size. Two blades that are reversely rotated into an angle stagger can break the PE foam wound on the adjacent blade, effectively improving the material winding. At the same time, PE foam crushed small pieces with uniform size and meeting the requirements of subsequent processing were obtained at the same time.

In addition, the double crushing of the Styrofoam densifier uses two crushing motors to provide more powerful power, and it is also suitable for hard materials, such as high-density polystyrene, XPS and EPP.