Polystyrene is used in products like foam packaging boxes, food containers and building insulation boards, it has been found to be a very practical plastic material, but difficult to deal with to some extent.

Due to the transportation problems, pollution issues and poor quality of the currently recycled polystyrene, this is the most non-recyclable plastic types as most people considered.

For the effective recycling of polystyrene, INTCO recycling has been exploring the industry for more than a decade, the polystyrene compactor launched in 2008 has been well received by the customers, and the brand name of INTCO’s foam recycling machine-GREENMAX has quickly occupied polystyrene recycling market in the world, which also promoted INTCO to continue its in-depth development in this field.

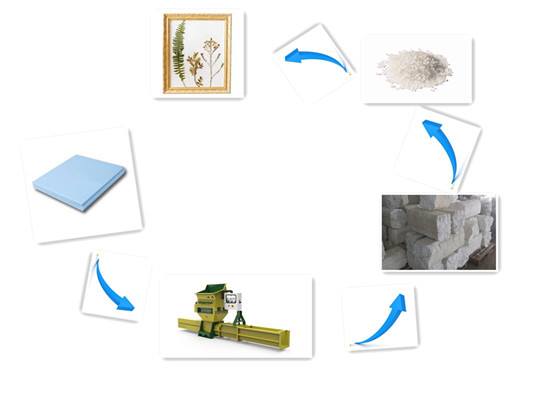

In the process of GREENMAX recycling machine, the polystyrene is placed in a crusher which can cut the loose foam into small pieces, for the larger size compactor, we need a conveyor belt to help us transfer the polystyrene materials stably and quickly to the crusher. The crushed foam then enters the screw compression box, there the polystyrene scraps will be compressed into dense blocks. The compression ratio of the polystyrene compactor is 50:1, which aims to reduce foam volume, save transportation costs and increase the value of polystyrene waste.

In addition to providing professional machinery and technical guidance for recycling companies, INTCO also has its own recycling business. The company buys compressed polystyrene foam blocks back to use it produce new foam products, such as picture frames and decorative moldings, and then sells them around the world. INTCO is a versatile manufacturer and recycling company, with a complete system of polystyrene recycling.

Polystyrene, which is considered a non-recyclable material has found its new life due to the application of GREENMAX foam recycling machines. We will persist in the field of recycling, and do better technical support and services.