Nowadays, plastic products have been widely used in all fields of production and life. As one of the four general plastics, expanded polystyrene(EPS) has a trend of increasing production and consumption year by year.

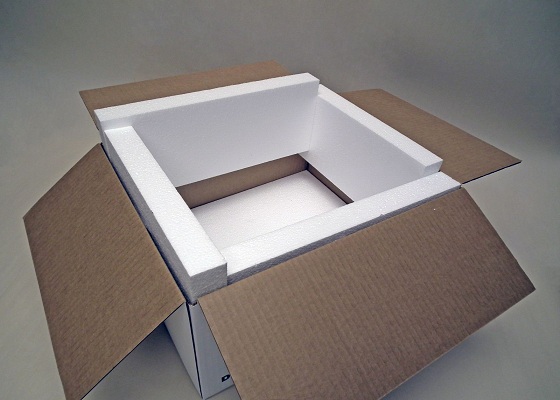

EPS is a very light material that can be processed into many different products. The main use of EPS is to create protective foams as packaging material that protect the goods in storage and transportation.

The material has the advantage of absorbing shock and low cost. In addition, EPS is a good insulator for transporting electronic components, food and medicine. Recycling EPS foam can be used to produce new materials such as hangers, foam wraps, CD cases and photo frames.

The first step for EPS recycling is to separate it from other wastes. The EPS is transported to a recycling plant where the EPS is broken down into pieces that are washed and compacted to produce PS pellets.

There are more than 200 EPS drop-offs in the United States. In 2013, 58 million kilograms of EPS was recycled, valued about 127 million pounds. About 57% of this waste comes from post-consumer packaging, and the remaining 43% comes from post-industrial packaging. In the past few years, the number of EPS entering the recycling sector has continued to increase. About 15% of EPS in the United States is recycled. Its recycling rate is the highest among all plastics.

The traditional disposal way of EPS waste is incineration or landfill. But these methods causes a series of problems such as occupying arable land, polluting the water source and discharging a large amount of waste gas. Therefore, many countries have turned the research that focus on EPS recycling. GREENMAX, as the American brand, has designed EPS compactor for all kinds of foam waste recycling. With the compression ratio of 50:1, the machine has gained much popularity around the world.

Thanks to our joint efforts, it is believed that the recycling rate of polystyrene will be greatly improved!