Only about two to five percent of a Styrofoam packaging material is polystyrene and the rest is air. Styrofoam has many benefits, including insulating ability that helps keep food warm. It is also of light weight, has high durability and strength, making it an excellent packaging material. Moreover, Styrofoam is hardly biodegradable. In the absence of a suitable solvent, Styrofoam can last almost forever.

If the Styrofoam materials are ingested by animals, it will often block their digestive tracts, cause starvation, and ultimately death. As such, it is important to dispose Styrofoam carefully.

Styrofoam is often space-consuming. It is estimated that by volume, it takes almost thirty percent of landfills worldwide. This situation adds on to the problem of disposing Styrofoam.

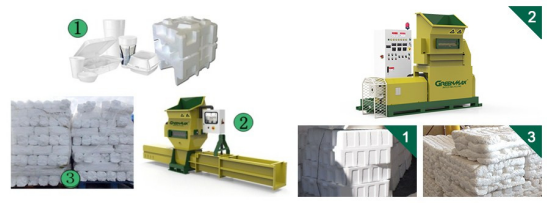

However, the recycling is not a difficult thing, if you use the right machine. GREENMAX is a kind of recycling company which can supply professional solution to the foam recycling. It’s compactors and densifiers can turn the foam materials into blocks or ingots. This is the very important first step for recycling.

Both of the compactors and densifiers can reduce the volume of foam materials. For the compactor, it can work at a ratio of 50:1. It means if you put 50 cubic meters of foam materials into the machine, after compressing, you will get 1 cubic meters of blocks. For the densifier, it can work at a larger ratio of 90:1. Both of the machines can help save much space and of course can save much costs.

Even though the foam materials are with large volume, with those machines, you will never have to concern about the solution to the foam materials. And recycling is much more environmental than the landfill.