The ubiquitous use of styrofoam in our daily lives, such as disposable coffee cups and break-proof heat shields in packaging boxes, has indeed brought great convenience to a fast-moving society that values efficiency. At the same time, the fact that polystyrene is difficult to degrade and difficult to recycle also places a huge burden on the earth’s natural environment.

Dart’s Drop

Dart, a giant disposable styrofoam tableware company that has generated huge amounts of money, has recently been questioned by environmentalists that its products are polluting the planet. Although they are arguing, Dart’s sales have indeed dropped a lot. An article in the New York Times titled “Your Foam Coffee Cup Is Fighting for Its Life”, author Michael Corkery talks about the opposition to Dart since last year, as well as some of Dart’s efforts and changes for this.

“We didn’t think it was good or objective to single out some of our particular materials (referred to polystyrene).”Jim Lammers, Dart’s CEO, said in a recent interview. They’ve been emphasizing for years that styrofoam can be recycled like any other material. But the recycling systems in most cities are reluctant to accept foam plastics because it is too difficult to find a buyer who is willing to pay the equivalent for these second-hand materials.

Battle of Styrofoam Recycling

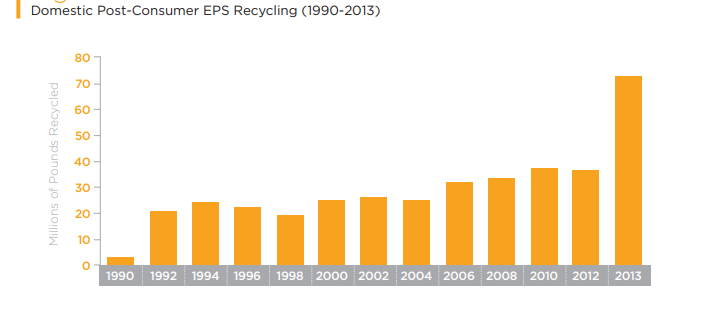

The styrofoam recycling problem is not just a worry for Dart. In many U.S. supermarkets, people are accustomed to carrying large and small commodities in plastic bags provided free of charge by stores, and the country consumes 100 billion plastic bags a year; In hotels and fast-food restaurants in the United States, only disposable foam tableware is generally provided, and restaurant trash cans are generally filled with such white garbage. According to a report of the 2013 US expanded polystyrene material recycling data released by the Expanded Polystyrene Industry Alliance (EPS-IA) in Maryland, the US EPS recycling rate in 2013 was only Only 34%, how to improve the efficiency of EPS recycling is still a problem to be solved urgently.

GreenMax EPS Foam Densifier

INTCO Recycling, as the biggest end-user and recycler of EPS foam scrap, has developed the GreenMax EPS Densifier for more than 10 years, helping the suppliers recycle their EPS foam scrap. GreenMax can densify the EPS scrap to blocks or ingot with the ratio 50:1 or 90:1, which can solve the transporting problem of the EPS foam recycling.

GreenMax Apolo C100 (Cold Densifier machine), for example, is one of the styrofoam recycling machines specializing in waste plastic foam recycling by screw compacting without heat and cold densified into compressed blocks. If you want to know more about the GreenMax machine, please visit http://www.styrofoamdensifier.org/.