EPS foam recycling is to make loose EPS waste to tight, high-density EPS blocks/ingots, which will then be granulated into PS pellets and made into new products like frames. During this process, an EPS foam densifier is of great importance and necessary.

However, what is the real function of EPS foam densifier, the foam recycling equipment which is widely used? The following will be discussed from two aspects.

Volume Reduction of EPS Foam Waste

For one thing, as the waste EPS foam is loose, large-volume, and easy to break, causing mass storage and hard manage. The transportation to deal with the EPS waste thus need much cost as it need the truck to pull away for times to times.

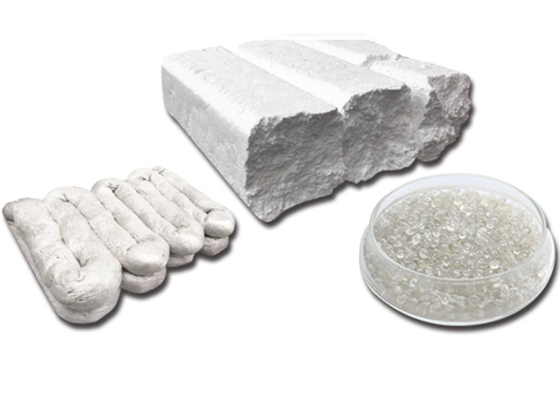

The EPS foam densifier, however, plays the role of volume reduction. It can reduce the foam volume at a ratio of 50:1 or 90:1, making the EPS foam easy to move, store and manage. It is also important that the compacted EPS can avoid the occurrence of fire and other hazards to some extent. Moreover, the cost on EPS foam transportation can be much reduced.

Improve Efficiency of EPS Foam Granulation

For another, we know that the ultimate goal of EPS foam recycling is to turn waste into treasure, that is to turn waste EPS into products that can be used. The premise of such a regenerated product can not be achieved without EPS foam granulation. Mixing different colors of foam pellets according to the formula to produce new products.

One of the important functions of the EPS recycling machine is to make the granulation process more efficient and superior. Compared with the loose EPS, the compacted tight EPS blocks and ingots can be granulated much easier and more efficient.

When you understand the real function of the above EPS foam densifier, it may be helpful for the EPS recycling action you are hesitating. It is not only a public welfare event to reduce pollution and protect the environment, but also a rare way for entrepreneurs to make profits.