The theme of world ocean day and national

ocean Publicity Day in 2022 is “protecting the marine ecosystem and

harmonious coexistence between man and nature”,

The report said that the impact of

disposable film plastic bags is particularly serious and should be banned or

phased out worldwide. To this end, the administrator of the United Nations

Environment Development Programme issued a special appeal to countries all over

the world to ban the use of disposable film plastic bags. The report points out

that plastic products, especially plastic bags and polyester bottles, are the

most common marine garbage. These plastic garbage slowly become smaller and

smaller fragments, which are swallowed by marine organisms. Their toxic

components are accumulating in organic organisms, which not only threaten these

organisms themselves, but also may enter the food chain, causing more

widespread harm.

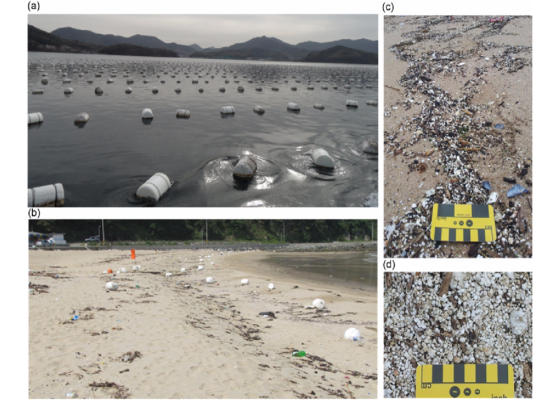

In fact, there is more than disposable

plastic film. The buoy in the ocean is also one of the ranking of marine

pollutants. Some buoys are mainly made of Styrofoam. Styrofoam is recognized as

one of the most difficult materials to recycle. Due to its large volume and

high transportation cost, it has not been well recycled.

As a

practitioner in the field of Styrofoam recycling, Greenmax received an order

for a Styrofoam compactor machine from Chilean guests. They are having a

headache for the recycling of marine styrofoam buoys. They have found many

enterprises that can not solve the problem for them. They see hope in Greenmax.

Why can the

recycling of marine Styrofoam buoy, which is a headache for everyone, be easily

solved by Greenmax foam recycling? We think the main reasons are as follows

1. Ten years of

deep cultivation and accumulated experience

INTCO Recycling

has been engaged in the foam recycling industry for more than ten years. We

have served nearly a thousand enterprises around the world. In the face of

customers in different industries, regions and recycling requirements, we have

been accumulating our experience while overcoming various problems.

Faced with the

challenge of recycling the marine foam buoy this time, Greenmax adjusted the

machine settings in combination with previous case design experience.

Considering the inevitable seawater in the foam and the corrosion of seawater

to the machine, the team adjusted the scheme for many times and finally

achieved perfect recycling.

2. professional

engineer team, R & D and improvement

Greenmax has a

professional R & D team of about 20 people. All our engineers are trained

internally. They spend every day in the factory and “fight” with

machines.

GREENMAX understand

customers’ pain points and are good at solving customers’ pain points through

equipment transformation. This Styrofoam compactor is a new challenge for

engineers. Fortunately, we have completed it perfectly.

Achieving customers

has always been the goal of Greenmax. What we provide is not only a Styrofoam compactor machine, but also a complete set of Styrofoam recycling system. Think what

customers think, so that we can put ourselves in a position to solve the pain

points and difficulties for customers.